About Rikon Veneer

The Rikon Message

- Sustainability is responsibility not a choice. We all have the moral obligation to preserve the planet resources so we and our mother nature can thrive together.Wood species used in making of reconstituted veneer have an average of 6-10 years from young to fully grown versus 80-150 years for most hardwoods of which natural veneer is cut.

THE RIKON CAPABILITY

- In Rikon, we are bound to keep developing new designs making sure whatever pattern or color we may not have in our collection is made and added to the range. Please don’t hesitate to share your desired pattern or color with us and we won’t spare an effort to develop it for you

THE RIKON APPROACH

- We strongly believe that our customers are the reason of our existence in business and they are the main drive for us moving forward. We believe satisfied customers are the only KPI by which we can measure our success. Honesty, Ethical Business Practice, Quality, Service and Very Affordable prices are the pillars on which we decided to build our business on.

THE RIKON COMMITMENT

- Rikon is committed to offering its customers the best and latest in trend reconstituted veneers with total and undivided awareness to quality and business practices.

THE RIKON PROMISE

- Our promise is to exceed clients expectations in quality, service and prices.

THE RIKON ADVANTAGES

- Grain and color consistency from sheet to sheet.

Defect-free veneers.

Sustainable.

Ideal sizes that reduce wastage.

Wide color and grain spectrum.

Endless design possibilities.

REALIZATION OF YOUR OWN DESIGN VISION IN WOOD VENEER

RIKON VENEER

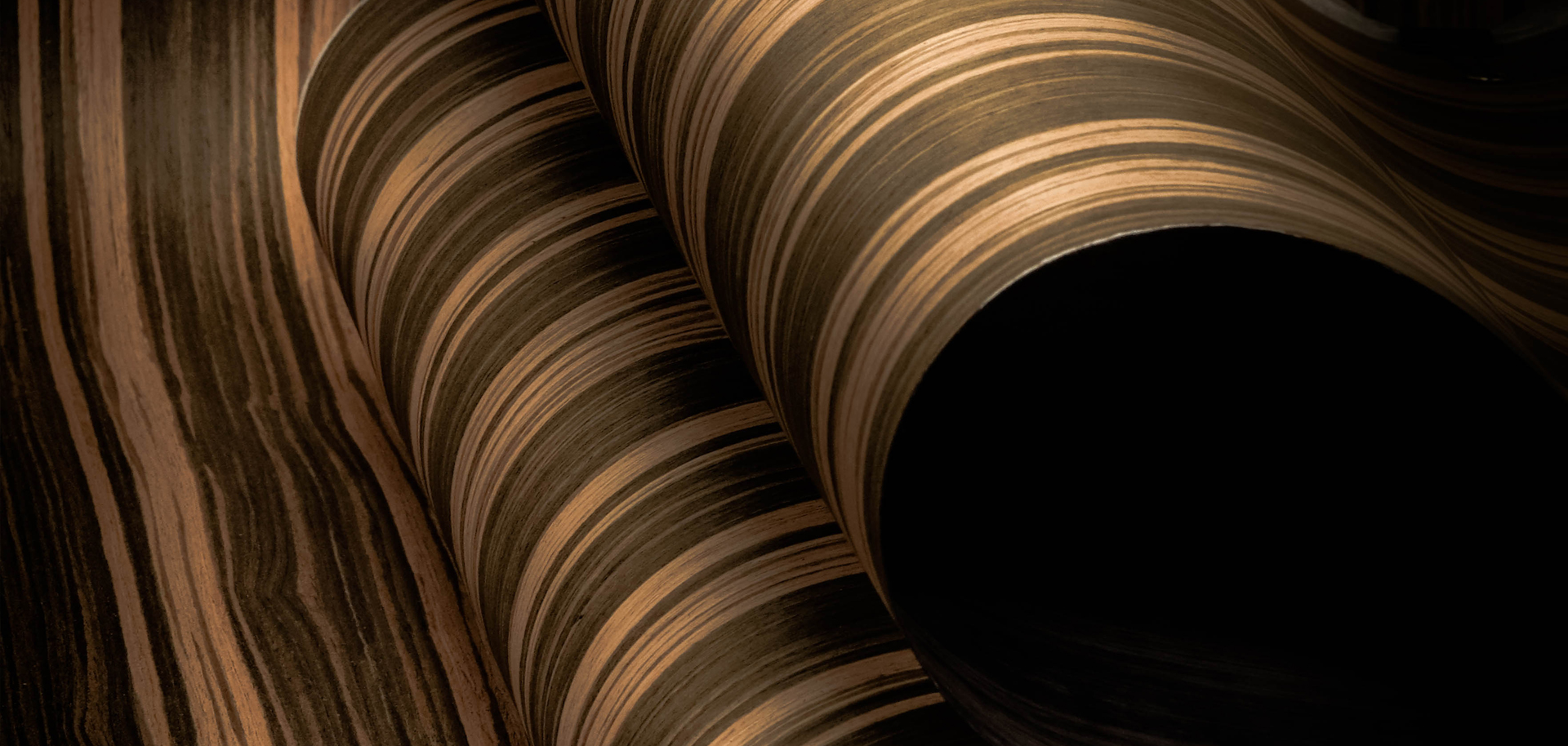

Reconstituted veneer is man-made veneer produced from fast growing wood species, laid and sometimes dyed to mimic the look of their real wood counterparts.

WHY RIKON

Backed with strong knowledge and long history in natural veneer and lumber industry and having witnessed and believed in the evolution of recon veneer, Rikon was established with the goal of offering its partners the latest in veneer trends and the highest quality in the industry with superior service and affordable prices.

HOMOGENEOUS AND DEFECT FREE

REAL WOOD VENEER VS RIKON RECONSTITUTED VENEER

- Real wood veneer is a thin layer of real wood. Wood is absolutely beautiful and it works with any design language but it has its own inherited challenges.

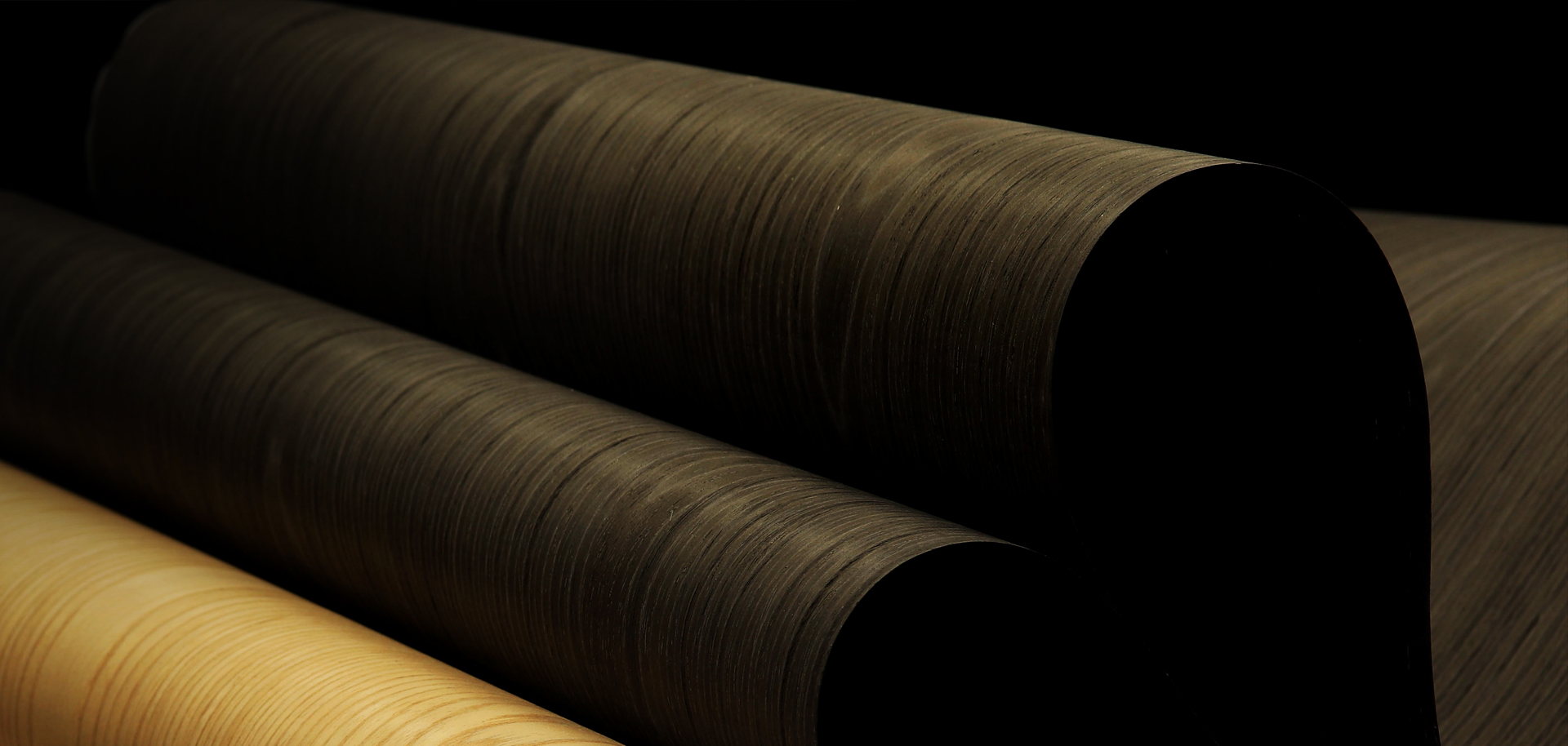

- Hardwood veneers are the main veneers in design and the average life of most hardwoods from small to fully grown harvestable tree is 80-150 years and that by itself puts a lot of pressure on environment and plant life as well as on designers torn between using wood and preserving the nature. In the same way, Rikon reconstituted veneer is also made of natural real wood veneer but the average life from small to fully grown harvestable trees of which Rikon is made of is only 6-10 years.

- Variations in real wood veneer quality and color shades often create unparalleled challenge to both designers and woodworkers who ,in some cases to overcome the color variation issue, they resort to lightly staining their veneer, a process that will surely reduce the natural esthetics of veneer when a layer of stain sits on top of veneer masking some of its fibers and pores. Rikon is consistent , homogeneous and when the desired color is unnatural, Rikon is dyed rather than stained and dye accentuates wood fiber details rather than hides them.

- The variety in sizes is always a challenge to woodworkers trying to keep their veneer wastage to a minimum without having to sacrifice quality in order to compensate for loss in sizes. Rikon is supplied in uniform format and multiple formats are available to order.

- Real wood veneer availability in certain quality , quantity and sizes is frequently a difficult especially when having a deadline to keep. Rikon is defect-free veneer, available in any quantity, in any color and in suitable cost effective sizes.

- Unlike real wood veneer, Rikon is available in various fancy decorative patterns that can meet designers creative designs at prices that don’t break the bank.

SUSTAINABILITY IS RESPONSIBILITY NOT A CHOICE

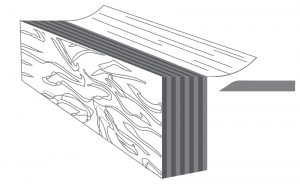

RIKON PRODUCTION STAGES

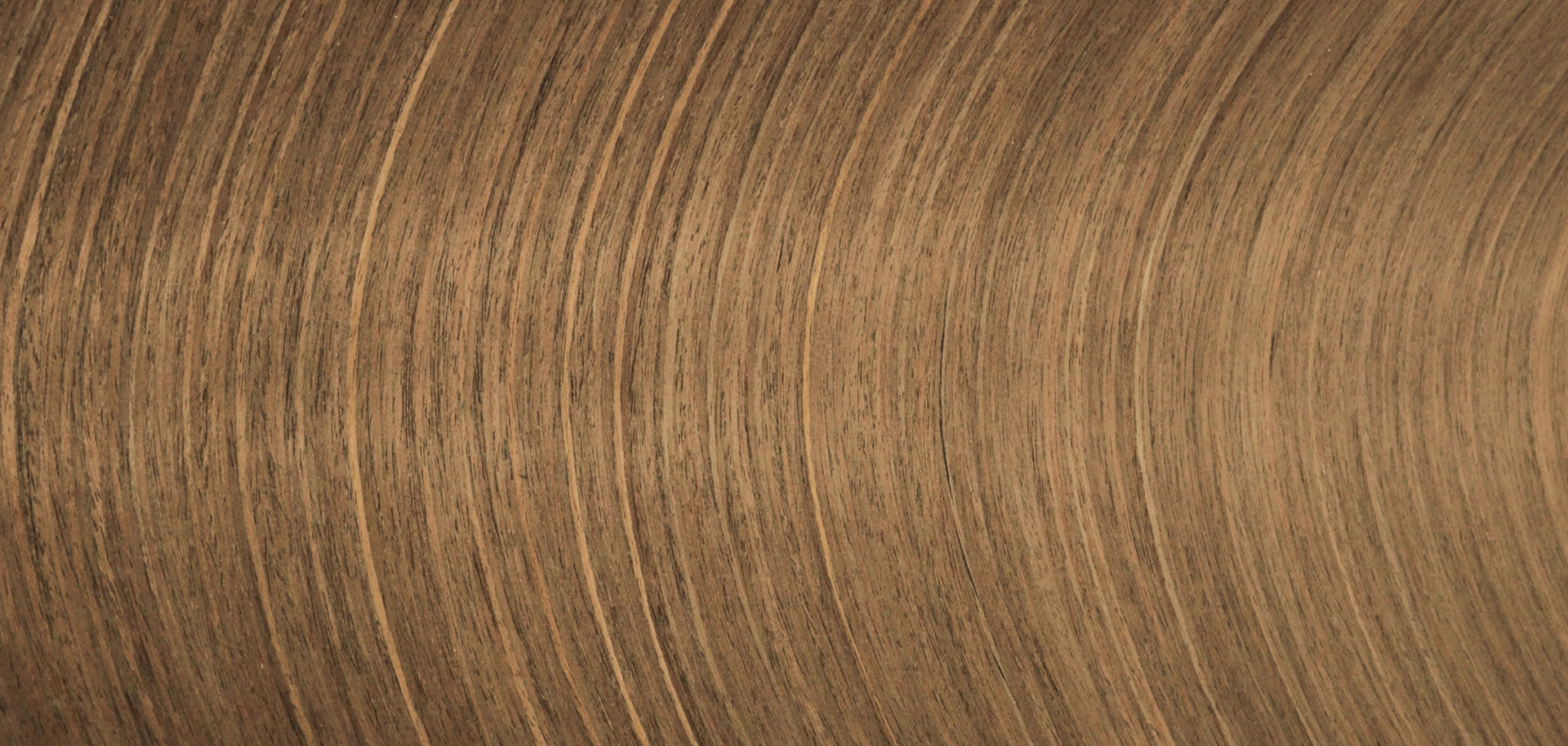

CUTTING LOGS INTO VENEER

DYEING

Rotary-cut veneer flitches are died in the desired final color.

.

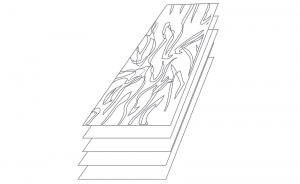

CREATING THE PATTERN

Different died veneer flitches in different color are mixed and laid together.

.

GLUING

The different layers of veneer flitches formed in the previous stage are then stacked and glued altogether in shape of a block. When necessary, glue can be tinted.

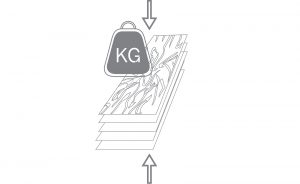

PRESSING LOGS

The cube shaped block is pressed. Some designs require flat press and some need wavy press platen to influence the final appearance of the veneer grain after the cured block is cut on its edge.

SQUARING & SANDING BLOCKS

After pressing, blocks are squared and sanded in preparation for the next step.

CUTTING | SLICING

After sanding, blocks are sliced on their edges to veneer that is now called reconstituted veneer.